Manufacturing industries are goods-processing industries, which are mainly own-account manufacturing industries, but also include the repair and installation of industrial equipment as well as subcontracting operations for a third party (INSEE).

ACCIDENTS:

- 2.3 million people worldwide die every year due to work-related accidents and diseases, which corresponds to more than 6,000 deaths per day (source)

- 250 million accidents with absence from work occur each year, equivalent to 685,000 accidents per day, 475 per minute and 8 per second (source)

MARKET:

- Manufacturing value added accounts for 15.40% of global GDP (2018). (source)

ACCIDENTS:

- The total direct and indirect cost of workplace injuries at a staggering $128 billion. (source)

- In the United States, workers operating or maintaining industrial machinery suffer more than 18,000 amputations, crushed fingers and other traumatic injuries each year. (source)

MARKET:

- Manufacturers account for 11.39% of the total output in the economy, employing 8.51% of the workforce. Total output from manufacturing was $2,334.60 billion in 2018. (source)

ACCIDENTS:

- In 2018, there were approximately 2,800 fatal accidents per 100,000 persons employed (source)

- In 2018, there were 3,445 non-fatal accidents per 100,000 people employed, yet France has the highest number of non-fatal accidents in the EU (source)

MARKET:

- In 2018, 2.8 million employees work in manufacturing, representing 11% of the total economy. (source)

Workplace safety is the leading trend for manufacturers heading into 2021, as it has gained new significance in light of the pandemic. New safety precautions are in practice, such as: social distancing measures on the production floor, sanitizing workspaces, monitoring who enters and exits facilities, and which individuals or equipment they interact with.

How Immersive Factory’s solution helps overcome this challenge:

Catalogue of more than 30 immersive learning exercises that allow faster and more effective learning than traditional training to effectively reduce the number of accidents.

Connecting man and machine: collaboration between humans and smart systems. Utilize digital technologies. Manufacturers should utilize new digital technologies that help them to become more efficient, more resilient, and more agile to prepare for the next normal.

How Immersive Factory’s solution helps overcome this challenge:

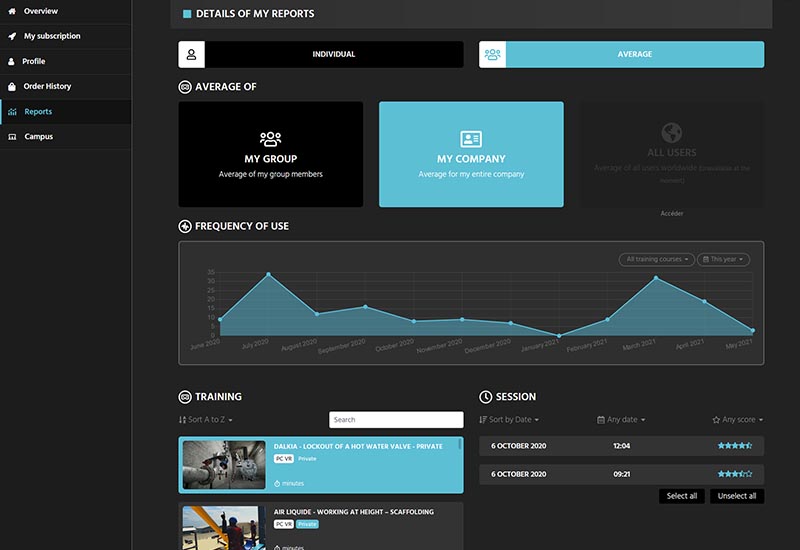

Immersive 3D & VR digital platform. The multi-device aspect allows each learner to train wherever they are.In a Deloitte poll (2021), 61% of surveyed executives are planning to develop a hybrid model for their production and non-production processes over the next three years.

How Immersive Factory’s solution helps overcome this challenge:

Customisable tool allowing the coherence of the actions of each site on a single tool, and multi-device allowing each learner to train safely, wherever they are. Intuitive back office and real-time access to key performance indicators (KPIs) allows constant monitoring of team efforts and achievements.

Safety training is the first means of prevention of industrial accidents. As social distancing measures continue to play a key role in protecting our wellbeing, there has been a rising need for professionals experienced in designing robust health and safety processes.

How Immersive Factory’s solution helps overcome this challenge:

Immersive Factory offers a vast catalogue of workshops allowing your employees to train in total autonomy. In fact, more than 30 gamified workshops are available for quick and immersive learning. Through an original and playful approach, and via a realistic virtual environment, workers can confront the risks they may potentially encounter in their workplace. Our active and serious games trainings are available in virtual reality or 3D simulation on PC. In addition, our ergonomic back office makes it possible to monitor in real time all the KPIs and statistics inherent to the actions carried out by the teams (procedural errors committed, comparison of results between the different sites, etc.). Our virtual campus, fully customizable, also allows you to organize and animate your safety days and HSE events remotely. There is no need for physical contact between the participants, the rules of social distancing are respected.There is resounding support for the benefits of apprenticeship schemes as a means to educate and empower employees and address the manufacturing skills gap. A vast majority of respondents (86%) agree that manufacturers have a responsibility to get more involved with schools and training. 72% of manufacturers see the development of apprenticeships as a positive thing for manufacturing, with 71% believing that apprenticeship schemes offer a viable alternative to other forms of higher education for school leavers.

How Immersive Factory’s solution helps overcome this challenge:

A very wide range of activities in VR or 3D simulation on PC offering workers a total immersion during which they will be fully active and 4 times more concentrated and emotionally involved than their counterparts in the face of a classical transmissive training (PwC, 2020).

Lean Manufacturing is a production methodology that focuses on reducing production costs. In a lean production environment, each process and activity is designed to add value to the customer and eliminate waste.

There are many types of waste (time, materials, etc.) that can occur in a manufacturing context. The goal of Lean Manufacturing is to identify and eliminate as many losses as possible. By doing so, manufacturers are able to increase the efficiency and productivity of their employees, as well as the quality of products.

One of the key concepts of lean production is known as the 'five S' These are the five organizational elements necessary for a lean production environment: SORT (eliminate what you don’t need), SET IN ORDER, SHINE, STANDARDIZE, SUSTAIN.

Implementing Lean Manufacturing can be a challenge for any organization, but the benefits are considerable. Organizations that have successfully implemented this process are seeing an increase in employee productivity, product quality and customer satisfaction. In addition, Lean Manufacturing has been shown to reduce production costs and lead times.

We offer engaging virtual reality training for your employees. With our team of experts, you can create tailor-made training modules adapted to the manufacturing sector.

The modules created can then be used and are made available to employees in an extensive way within the company.

Thanks to VR, our modules are simple to implement, and above all much more effective than traditional training.

Discover them through the testimonial from Imerys which has co-developed with Immersive Factory a VR training module to raise awareness among their teams about the manufacturing occupational risks:

Imerys Testimonial: looking back on the creation of a VR module

ABOUT IMERYSImerys is a French group and the world leader in specialty minerals for industry. Imerys provides high value-added functional solutions for a wide range of sectors, from process industries to consumer goods.Imerys is also :3.8 billion € in revenues ...

See moreThey trust us