Hazard Spotting - Concrete mixing plant

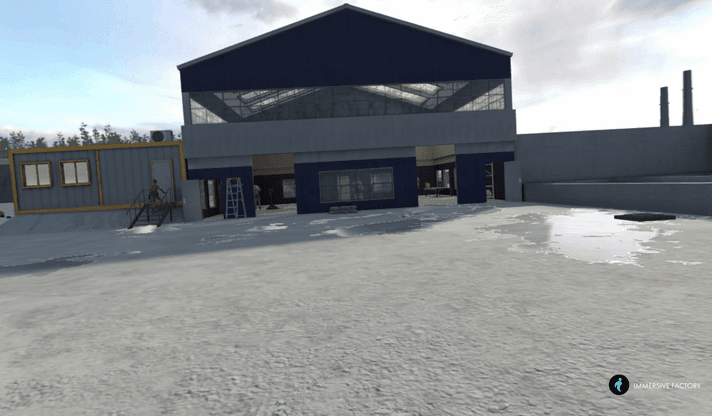

The Hazard Spotting - Concrete plant course in virtual reality raises awareness among your teams about the identification of hazardous behaviours or situations in a concrete plant that is virtually recreated as close as possible to reality.

The benefits of the VR-based Hazard Spotting - Concrete mixing plant course

• Active learning where trainees remember 90%* of what they do

• Real-time statistics on the procedural errors made.

• Innovative management tool for debriefing and leading change

Hazard Spotting - Concrete mixing plant course objectives

Hazard Spotting - Concrete mixing plant course is part of the company's safety policy and aims to contribute to the reduction of workplace accidents. There are hidden risks in a virtual concrete plant. These risks appear randomly, depending on the duration of the exercise chosen by the trainer.

For trainees:

• Identify the hazardous situations and high-risk behavior appearing at random in the virtual warehouse.

• View the corrections sheet at the end of the exercise to measure the number of errors identified and review the procedures for any errors that have gone unnoticed.

For the company:

• Reduce the frequency rate of work-related accidents.

• Familiarize employees with best health and safety practices.

• Raise awareness and produce a long-term influence on behavior with virtual reality.

• Catch your employees' attention more effectively by offering them an innovative training approach.

Target audience for the Hazard Spotting - Concrete mixing plant course

• All employees working in a concrete plant

Equipment required

A standalone VR headset. With an Internet connection, you can view your reports and update your courses.