Hazard Spotting - Chemical Factory

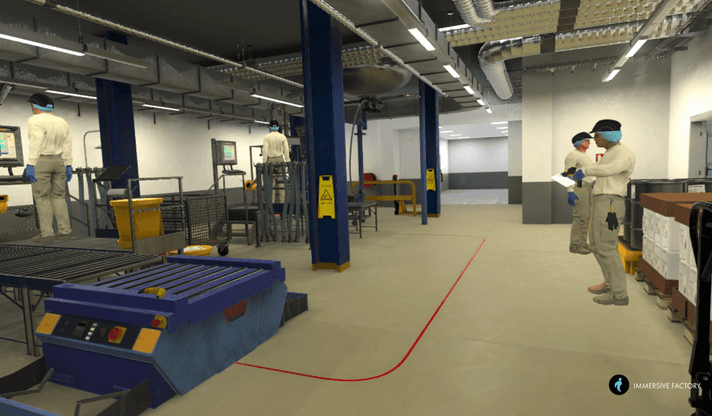

Hazard Spotting - Chemical Factory is a Virtual Reality training course that raises awareness among your teams about the visual detection of hazardous behaviours or situations, in a chemical manufacturing plant.

The issues of the training

In a chemical plant, exposure and handling of hazardous materials can be dramatic when safety safety procedures are not correctly followed. Mislabelling and storage errors, failure or improper wearing of Personal Protective Equipment (PPE), inhalation, ingestion, fire… are all risks to be identified and prevented.

The benefits of the VR-based "Hazard Spotting - Chemical Factory" course

People learn and understand best when they interact with a ressource (learning by doing instead of learning through abstraction). Indeed, an individual retains 20% of what he heard and retains 90% of what he felt. Through our VR-based course, your employees confront risks related to the non-compliance of safety rules when working in a chemical plant. Our 3D virtual environment provides a fairly faithful representation of reality and a sensory based learning style. Furthermore, real-time statistics on the procedural errors made are available as well as an innovative management tool for debriefing and leading change.

"Hazard Spotting - Chemical Factory" course objectives

"Hazard Spotting - Chemical Plant" course is part of the company's safety policy and aims to prevent work-related risks inherent to exposure and handling of chemicals. Its objectives are to prevent and reduce workplace accidents by identifying risks, reminding security procedures and acquiring good practices in the workplace.

- Simulation in a 3-dimensional environment that provides a fairly faithful representation of reality,

- Identification of 35 material and behavioural risks present in a chemical plant (labelling, PPE, exposure, contamination, storage...),

- Reminder of safety procedures and preventive actions,

- Personalization of sessions and present risks,

- Active pedagogy involving the learner,

- A statistical reporting and remediation system that ensures procedures are reminded and training is followed.

For trainees:

- Be aware of the risks associated with exposure and handling of chemicals,

- Identify and prevent these risks in the workplace (mixing, packaging, storage),

- Knowledge of safety procedures and preventive actions,

- Identify the hazardous situations and high-risk behavior appearing at random in the chemical plant,

- View the corrections sheet at the end of the exercise to measure the number of errors identified and review the procedures for any errors that have gone unnoticed.

For the company:

- Reduce the frequency rate of work-related accidents,

- Familiarize employees with best health and safety practices,

- Raise awareness and produce a long-term influence on behavior with virtual reality,

- Catch your employees' attention more effectively by offering them an innovative training approach.

Target audience for the "Hazard Spotting - Chemical Factory" course

- All employees working in a chemical plant.

Equipment required

A standalone VR headset. With an Internet connection, you can view your reports and update your courses.